Structural Engineering and Materials Lab

The Department of Civil, Construction and Environmental Engineering at the University of New Mexico has three well-equipped laboratories in which the physical and mechanical properties of Civil Engineering Materials are evaluated.

These three laboratories include:

* The mechanics of materials laboratory where students test the behavior of metals (steel & aluminum) and timber.

* The concrete laboratory where students evaluate concrete aggregates, portland cement and portland cement concrete (PCC).

* The bituminous laboratory where students test asphalt binders and hot mix asphalt (HMA).

Structural and Materials Testing Facilities UNM

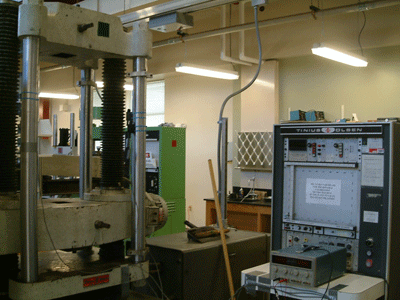

The new Centennial Engineering Center (CENT) at UNM houses the Structural Engineering Laboratory where materials and structural testing is performed. The figure below shows some of the testing equipment and testing facilities available for structural engineering.

Structural lab equipped with state-of-the-art testing equipment for materials and structural testing.

Photo shows Dr. Taha and some of his research team members.

Low Velocity Impact Machine with External Frame Actuator

Environmental Chamber

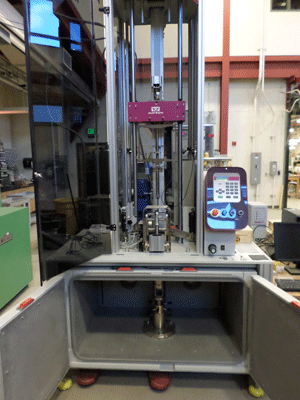

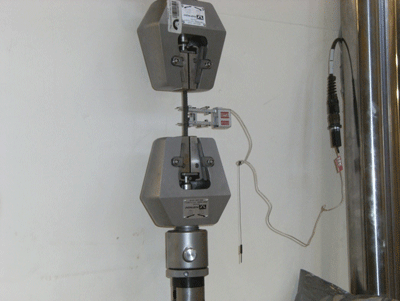

25 kN MTS Servo-Control Universal Testing 100 kip Instron Servo-Control Universal Testing Machine

Machine Typically Used for Testing Composite

Coupons

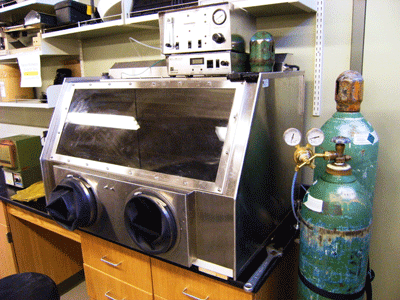

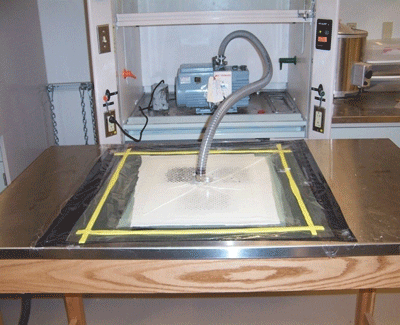

400 Kip Servo-Control Testing Equipment Glove Box for Nano0synthesis

Tension Test Apparatus Composite Fabrication Platform

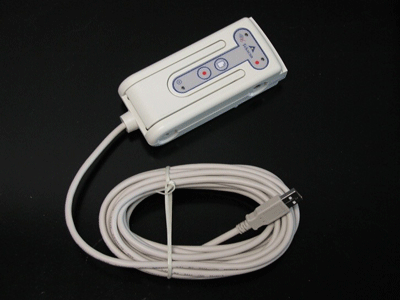

16 Channel Data Acquisition System 64 Channel Data Acquisition System

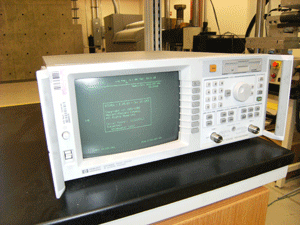

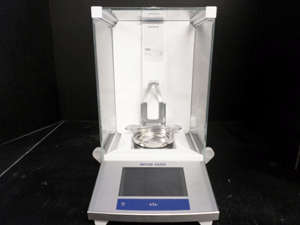

Network Analyser Digital Balance for Density Measurements

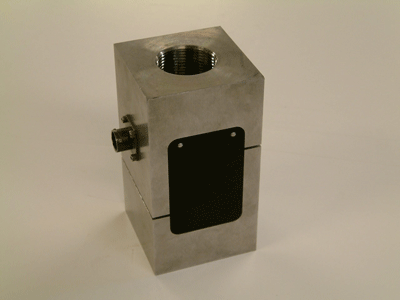

Tekscan Pressure Gauges 50 and 100 Kip External Load Cells

Nanoparticle Sonication

Ultra Shear MIxer for Dispersing

Nanoparticles

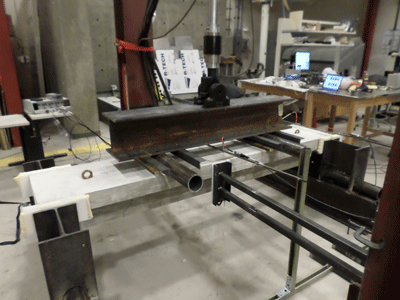

High bay for structural testing with reaction wall and 100 kip structural frame. The high bay frame configurations enable testing large scale

concrete and steel structures. Testing frame was also used to test concrete structures strengthened with FRP and wood joists.

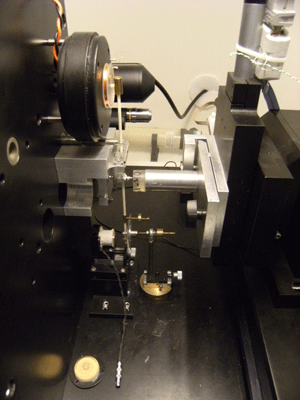

Nanoindenter (located in the Mechanical Engineering Department)

The NanoTest system is a fully flexible nanomechanical property measurement system. It is capable of measuring hardness, modulus, toughness, adhesion, and many other properties of thin films and other surfaces. Load ranges can be from sub-mN to 500 mN, and sample environments and impacting conditions can be set to closely replicate conditions that these materials actually see in–use.